The L1 series consists of five variants, three produced in Britain (L1A1, L1A3, & L1A4), one produced in Australia (L1A2) and Canada (C1), and one produced in India (1A). The British, Australian, and Canadian bayonets are very similar, differing in minor respects. The Indian bayonet is closely patterned on the British L1A4, but departs from the L1 pattern in having wooden grips. Some 1A bayonets also had a longer blade.

Australia—L1A2

The L1A1 and L1A2 bayonets are very similar, both featuring a protruding press stud. The L1A1 has a square fuller, while the L1A2 can have either a square (pictured above) or rounded fuller (pictured below). The L1A1 was used by Britain and has identifying markings on the ricasso and grip. The L1A2 bayonet was produced by Australia and Canada (where it was designated C1). The Australian bayonet is devoid of markings.

The L1A2 was produced at the Small Arms Factory, Lithgow, from 1958–1984. The earliest L1A2 bayonets, such as this one, had the squared fuller like their British and Canadian counterparts. Australia changed to the unique rounded fuller in 1960. I had long thought the bayonet pictured above to be a Canadian C1, due to the square fuller. However, L1A1 Collector and Researcher, Kevin Adams, pointed out that the L1A2's assembly slot in the pommel is straight and the Canadian version is T-shaped, as shown in this comparison image.

The L1A2 bayonet and scabbard pictured below were still packed in cosmoline when I received them. The Australian L1A2 scabbard is somewhat more pointed than the British No. 5 Mk. I pictured along with the L1A4 bayonet below.

Britain—L1A3

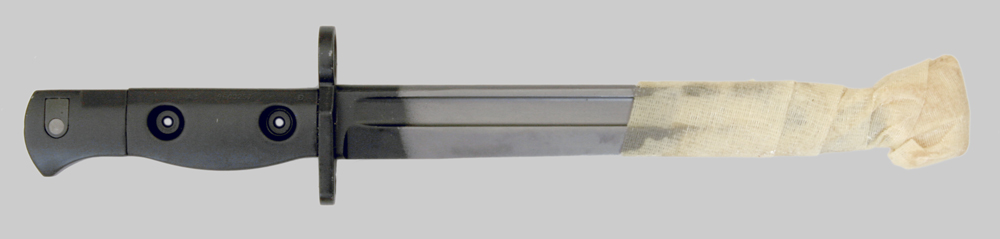

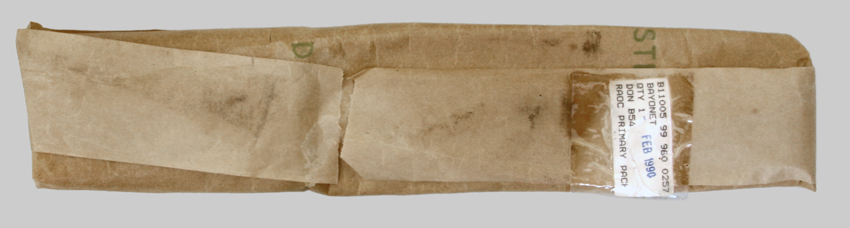

The L1A3 bayonet was introduced into British service during the late 1950s to eliminate the protruding press stud used on the L1A1 and L1A2 designs. It was felt that the protruding press stud made the bayonet too easily dislodged, so the press stud was made flush with the pommel. This example was made at the Royal Small Arms Factory, Enfield in 1959. It had been reconditioned and was still in the government packaging when I received it. I carefully removed it from the packaging in order to photograph it, but never unwrapped the point.

In the mid-1960s, the L1A3 blade fuller was shortened, creating a very long ricasso. It was perceived that the fuller extending almost to the crosspiece weakened the blade. Late L1A3 bayonets also introduced a simplified crosspiece, lacking the "waist" found on earlier examples. This example was made in early 1967 at the RSAF Enfield.

Britain—L1A4

The L1A4 bayonet was approved in the late 1950s, however, was not produced until the 1970s. Most of the differences are in its internal construction. The L1A4 used the simplified crosspiece, introduced on late L1A3 bayonets, but returned to the long fuller. The L1A4 bayonets were made by Hopkinson Ltd., a Sheffield firm. This example was made in 1973. Note how much more rounded the British No. 5 Mk. I scabbard pictured below is than the Australian L1A2 scabbard pictured above.

Canada—C1

The C1 is the L1A2 as manufactured in Canada. The C1 differs from the Australian L1A2 by having the pommel secured to the tang by rivets, where the L1A2 pommel is brazed to the tang. The C1 assembly slot in the pommel is T-shaped, where the L1A2 assembly slot is straight, as shown in this comparison image. The C1 bayonet was produced 1956-66 by Canadian Arsenals Ltd., Long Branch, Ontario, Canada. The number on the crosspiece face is the part number portion of the NATO Stock Number for bayonets. The upper portion of the sheet metal grip on this example is pushed in a bit. The scabbard is the No. 5 Mk. I.

India—1A

The Indian variant of the FAL was designated the 1A Self Loading Rifle (SLR). It was a reverse-engineered copy of the FAL that incorporated a mixture of inch-pattern and metric FAL features. The Indian 1A bayonet is closely patterned after the British L1A4 bayonet, except that it has wooden grip scales. This was probably a better choice than sheet steel for the tropical Asian climate. As with the L1A4, it has the recessed press stud, the simplified crosspiece, and the pommel is riveted to the tang.

India produced two versions of the 1A bayonet, one with a standard 8-inch blade and one with a longer 10-inch blade. The standard 1A bayonet used the British No. 5 scabbard, as was used with the L1 series bayonets. 1A bayonets with the standard length blade are scarce. Heavily worn, to say the least, this is the only example that I have ever encountered.

The 1A long variant is the longest of all FAL bayonets. 1A long blade bayonets are uncommon, but not nearly as scarce as the standard-length variant. Most are found in good condition, but without scabbards. The scabbard is a crude, longer copy of the British No. 5. This example was made in 1967 at Rifle Factory Ishapore.

Turkey—G1

In the early 1960s, Turkey received G1 rifles from Germany, who had procured 100,000 from FN, but then changed to the G3 rifle after FN refused to allow Germany to produce the G1 under license. The Germans did not issue a bayonet with the G1, so Turkey added a bayonet lug to the G1 barrel and produced this makeshift knife bayonet. Crudely constructed of a new made pressed steel hilt mated with a recycled blade from an earlier Mauser bayonet. Several variations in blade, crosspiece, and muzzle ring have been observed. The scabbard is recycled from an earlier Mauser bayonet. Again, many variations in scabbard design have been observed.

Page 2—Additional FN FAL Type C Bayonet Variations

Bayonet Identification Guide Index

© Ralph E. Cobb 2009 All Rights Reserved