| Pictures (click to enlarge) |

Type | Description | Blade Length |

Overall Length |

Muzzle |

Markings | |||

| in. | mm. | in. | mm. | in. | mm. | ||||

|

No. 4 Mk. I |

The No. 4 Mk. I was beautifully made, with its distinctive cruciform blade. The bayonet and socket were one solid forging.

Only 75,000 of this type were made. Production occurred during the latter half of 1941 and into the early months of 1942. The only maker was the Singer Manufacturing Co. (the famous sewing machine people), at their Clydebank, Scotland plant. One influence in the selection of Singer was that Scotland was felt to be safer from German bombers than England. |

8.00 |

203 | 10.00 |

254 | .595 |

15.1 | No. 4 Mk. I markings were reminiscent of how Pattern 1907 bayonets were marked, with the royal cypher, type, and maker.

Socket: "G (Crown) R" over No 4 Mk I" over "S M" Blade (flute): Broad Arrow over "22" (in electropencil) Spring Catch: "SM" over "41" |

|

No. 4 Mk. II | The No. 4 Mk. II was a simplified version, eliminating the milling cuts required to create the cruciform blade flutes. The No. 4 Mk. II was otherwise identical to the Mk. I, with the bayonet and socket one solid forging.

Three firms produced the No. 4 Mk. II: Singer in Scotland, the Savage Stevens Co. in the USA, and Long Branch in Canada. The No. 4 Mk. II was, by far, the most numerous variant, with over 3.3 million units produced.

| 8.00 | 203 | 10.00 | 254 | .595 | 15.1 | |

|

Singer Manufacturing Co. | Singer produced 1,141,782 No. 4 Mk. II bayonets from 1942–1944. | Singer continued using a similar markings, as used on the Mk. Is, until the government created the dispersal codes in 1943. From 1943 onwards, Singer bayonets bore their dispersal code, N67.

Occasionally, viewer's (inspector's) marks are found on No. 4 bayonets. An example of a viewer's mark "75TZ" is pictured at left. The last picture illustrates an unusual mark, occasionally found on No. 4 bayonets. The significance of this mark is not known. |

||||||

|

Small Arms Ltd. (Long Branch) | The Crown Corporation Small Arms Ltd., Long Branch, Ontario, Canada, made approximately 910,000 No. 4 Mk. II bayonets from 1942–1944.

This example bears the Canadian Government acceptance mark, indicating use by Canadian Forces. | Long branch bayonets are marked with a superimposed "L" and "B".

The example pictured at left also carries the Canadian "broad arrow" mark, indicating acceptance into Canadian service. | ||||||

| Savage-Stevens Co. | The Savage-Stevens Co. of Chicopee Falls, Massachusetts, made approximately 1.25 million No. 4 Mk. II bayonets during 1941 and 1942. These were provided to Britain under the Lend-Lease Act. Savage-made bayonets are much cruder forgings than those made by either Singer or Long Branch.

The Savage-Stevens plant in Chicopee Falls was where New England Westinghouse produced Mosin-Nagant M1891 rifles in 1915–1917 under contract to the Imperial Russian government.

| Savage marked their bayonets with the letter "S". Five distinctly different markings were used (all are pictured at left):

2 mm. deeply-struck "s" Savage was the only other maker to follow Singer's pattern of marking the spring plunger. Savage used variations of both a plain "s" and an "s" inside a Square. |

|||||||

|

New Zealand Issue | No. 4 Mk. II made at LongBranch in Canada. Carries the electropenciled New Zealand property marking and serial number.

These bayonets equipped the 2nd New Zealand Expeditionary Force. The 2nd NZEF fought in the North African and European Theatres as part of the British 8th Army. Based on serial numbers observed, approximately 35,000 No. 4 bayonets went to New Zealand. | Socket: N (arrow) Z over "24637" | ||||||

|

Turkish Issue | Little is known about these British No. 4 spike bayonets used by Turkey. Most examples observed are of USA or Canadian manufacture. This example was made in the USA by the Savage Stevens Co. of Chicopee Falls, Massachusetts.

A quantity of No. 4 rifles were imported to the USA from Turkey in the mid-2000s. These rifles can often be identified by the stacking hook welded to the upper band. This example came in a modified Turkish belt frog. |

Socket: "No 4 Mk II" over "S" and "B 75" over "1455"

Spring Plunger" "S" |

||||||

|

Canadian Arsenals, Ltd. | Canadian Arsenals, Ltd. was the post-war successor to Long Branch. Canadian Arsenals produced a run of approximately 5,000 No. 4 Mk. II bayonets during the Korean War. These were the last No. 4 socket bayonets produced.

The Canadian Arsenals trademark was adopted in 1947 and replaced the Long Branch trademark used during the Second World War. |

Canadian Arsenals marked their bayonets with an "A" nested inside a "C". | ||||||

|

No. 4 Mk. 2 | In September 1945, nomenclature was changed to replace Roman numerals with Arabic numerals. For example, No. 4 Mk. II became No. 4 Mk. 2.

This example was reworked post-War following the change from Roman to Arabic numbering. The remnants of the wartime marking are lined through and the new marking applied above. |

Socket: "No. 4 Mk. 2" | ||||||

| No. 4 Mk II* | The No. 4 Mk. II* (pronounced: number four, mark two, star) was a further simplified version, with the socket and blade two separate forgings. This lowered costs and allowed manufacture by subcontractors. This also disbursed production, mitigating the risk of production being interrupted by bombing. Two-piece construction gives the No. 4 Mk. II* its characteristic stepped join between blade and socket.

Four firms produced the No. 4 Mk. II*, all in the UK: Prince-Smith & Stells, Howard & Bullough, Lewisham Engineering, and the Baird Manufacturing Co. 1.4 million No. 4 Mk. II* bayonets were produced, over a million of which were produced by Prince-Smith. The other makers were much less prolific. The finish varies considerably between manufacturers, with Baird bayonets approaching the excellent finish of the No. 4 Mk. I and some Prince-Smith examples exhibiting rough tool marks. | 8.00 | 203 | 10.00 | 254 | .595 | 15.1 | ||

|

Prince-Smith & Stells Co. | Prince-Smith & Stells in Keighly, Yorkshire, produced 1,057,515 No. 4 Mk. II* bayonets from 1942–1945.

Before the war, Prince-Smith was a manufacturer of machinery for making woolen textiles. The "circle-PSK" marking is somewhat of a mystery and is seldom encountered. According to Graham Priest, on a rough scale of observations, he indicated that you see 100 P.S.& S. Ltd for every circle mark; 150 P.S.K for every circle mark, and 500 N56 or unmarked for every circle mark. | Prince-Smith used four different markings:

P.S.K. In 1943, Prince-Smith was assigned the dispersal code N56. The last picture shows an unusual Prince-Smith mark comprised of a large "56" on the socket face. | ||||||

|

Howard & Bullough Co. | Howard & Bullough Co. of Accrington, Lancashire, was one of the smaller makers of the No. 4 Mk. II*, with approximately 161,026 reported produced, during 1942–1943.

Howard & Bullough converted from the manufacture of cotton spinning machines to the production of shells, gun carriages, mine sinkers, aircraft components, and bayonets. The company disappeared in 1970. | Howard & Bullough marked their bayonets three different ways:

H&B | ||||||

|

Lewisham Engineering Co. | Lewisham Engineering, at 9 & 11 Malyons Road, Ladywell, London, was the smallest maker of the No. 4 Mk. II*, with approximately 84,566 reported produced from 1943–1945.

The company was established on the bombed out site of the South East London Indoor Sports Club (destroyed in the blitz bombings of 1940–41), solely to make bayonets. The factory was built by working around the clock during 1942 and was provided with capstans, drilling and milling machines, centre lathes, a steel-hardening and processing plant, and a centre-less grinding machine. The factory eventually went on to produce cylinder heads for Davey-Paxman landing craft engines. The factory site was razed to accommodate (apartment) flats in the mid-1980s. | Lewisham marked their bayonets with "L. ENG. over S376, inside a rectangle.

S376 was Lewisham's dispersal code. | ||||||

|

Baird Engineering Co. | Baird Engineering Company of Belfast, Northern Ireland, produced approximately 101,103 bayonets from 1942–1944.

Unlike other makers of No. 4 Mk. II* bayonets, Baird secured the spike to the socket using a steel pin. Other makers welded the spike to the socket. This example has a much finer finish on the socket than other No. 4 Mk. II* bayonets. Many Baird examples have a crowned IG mark on the socket. Due to similarities with Indian Government acceptance marks, this was once thought to possibly indicate Indian service. However, this has not been substantiated. An increasing consensus is that this simply may be a viewer's mark, as this mark seems only to be found on Baird No. 4 bayonets. | Baird marked their bayonets two different ways:

BEC N96

N96 was Baird's dispersal code. | ||||||

|

Questionable Australian Issue | Some No. 4 Mk. II* bayonets have been observed with an arrow over "D" marking on the front of the socket. This symbol is similar to the Australian Defence Dept. ownership marking.

It was thought that these may have been used by Australian units serving alongside the British Army, however, Australian issue of these bayonets has not been confirmed. An increasing consensus is that this simply may be a British viewer's mark, as this mark seems only to be found on Prince-Smith examples. |

Broad arrow over "D" | ||||||

|

Jordanian or Iraqi Issue | This PSK No. 4 Mk. II* bayonet has Arabic markings on the socket. Most likely Jordanian from the Arab Legion, but could also have been used by Iraq.

According to Jordanian collector/ researcher Ahmad Hatamleh, Jordan and Iraq were the two countries in the Levant where the British helped establish their national armies. Prior to obtaining independence in 1946, Jordan was a British Protectorate, known as Transjordan. The British No. 4 Mk. II* socket bayonet was used in Iraq during the Second World War and by the Iraqi Army after the end of British occupation in 1947. |

Socket (left): partial PSK mark

Socket (right) "VNS" Socket (right): |

||||||

|

Royal Air Force | "AM/712" indicates procurement via an Air Ministry (RAF) contract. The socket was forged by Viners Ltd. | |||||||

| Forging Contractor Marks | Subcontractors produced many of the No. 4 Mk. II* socket forgings. The pictures at left illustrate some of the forging marks. Forging subcontractor marks tend to be very deeply struck.

Recent research by Graham Priest determined that "TRM.1", "TRM.2", and "TRM 3" identify the Tinsley Rolling Mills Co. Ltd. of Sheffield. This mark sometimes appears alone and sometimes with another forging contractor’s mark, which suggests that Tinsley supplied steel to several of the socket forging contractors. |

"VNS" = Viners Ltd., Sheffield.

"F.F. & S. Ltd." = Fred Fisher & Sons Ltd. "JW (S) Ltd." = John Wilson Ltd., Sheffield "TRM.1", "TRM.2", and "TRM 3" = Tinsley Rolling Mills Co. Ltd. of Sheffield

| |||||||

|

Belgian | This example was manufactured post-War for Belgium.

Little is known of their manufacture and use. The maker is unknown, but is believed to be Belgian. The bayonet exhibits better finishing than most British No. 4 Mk. II* bayonets. The period of manufacture is believed to be late-1940s or early-1950s. The Belgians received Lee-Enfield No. 4 rifles and bayonets after Belgium was liberated in September 1944. The Belgian Army transitioned to the FN Model 1949 rifle beginning in 1951. However, the Rijkswacht (Gendarmerie) used the No. 4 rifle into at least the 1960s. Both bayonet and scabbard are serial numbered. This suggests production by a private contractor that was paid according to the number of pieces accepted. Serial number observations suggest about 7,000 were made. |

Socket: "No. 4 Mk. 2" over "Bg" over Crown-JF proofmark over "5171"

Scabbard (mouthpiece): "5171" Scabbard (frog stud): "Bg" over Crown-JF proofmark |

||||||

|

No. 4 Mk. III | The No. 4 Mk. III was the final, and crudest, form of the No. 4 spike bayonet. The socket is fabricated by welding together seven sheet steel stampings, eliminating the socket forging process altogether. Even the spring plunger is a stamping.

196,200 were produced, all by Joseph Lucas Ltd., Chester Street, Birmingham. The No. 4 Mk. III was declared obsolete in 1946.

| 8.00 | 203 | 10.00 | 254 | .595 | 15.1 | Lucas marked the bayonets with M158 on the top of the socket.

M158 was their dispersal code. The rod of this example is marked S7, indicating manufacture by subcontractor Auto Engineering Ltd. of Croydon. Auto Engineering produced approx. 30,000 rod forgings. |

|

Packed in Mineral Oil | This No. 4 bayonet is coated with PX4 mineral oil (grease), in a green waxed "primary pack" wrapper. | None. | ||||||

|

Repacked in Waxed Paper Wrapper | The labelling indicates that this No. 4 bayonet was repacked in September 1986 at Building 3 of the Royal Army Ordnance Corps' Central Ordnance Depot, Donnington.

This illustrates just how long after their obsolescence, that bureaucratic inertia can demand retention of items in military stores. |

Label:

BI-1005-99-961-7794 |

||||||

|

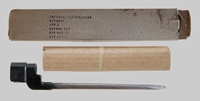

Packed in Cardboard Box | (2) Canadian No. 4 Mk. II bayonets packaged in a cardboard carton.

The bayonets are coated with mineral oil (grease), in a waxed "primary pack" paper wrapper. The box label indicates that these were packed July 8, 1957, at the 5th Storage Depot, Moncton, New Brunswick. |

Label:

Stock No: 7B/546 |

||||||

|

Packed in Cardboard Box | Longbranch No. 4 Mk. II bayonet re-packaged in 1963 cardboard carton.

The box label indicates that these were packed November 1963, at the 5th Storage Depot. |

Label:

7B/1005/21/103/1147 Socket: "No 4 Mk II" over a superimposed "LB" Spike: C-Broad Arrow acceptance mark (electropenciled). |

||||||

| Point Wrapped in Wax-Impregnated Fabric | After wrapping the point, this bayonet would have been oiled and sealed in clear plastic. | None. | |||||||

Scabbards |

Four scabbard designs saw significant use with the No. 4 bayonet.

| ||||||||

|

Mk. I | The No. 4 Mk. I is the most commonly encountered scabbard, outnumbering all others combined. It has a tapered steel body with a ball finial. A drain hole in the finial, allows water to drain. A round frog stud is brazed to the body. | n/a | 8.25 | 210 | n/a | This Mk. I scabbard may have been made in the USA, given the lack of any maker's or proof marks. According to Skennerton, more than 2 million Mk. I scabbards were made in the USA.

|

||

|

Mk. I Mouthpieces | Four mouthpiece materials have been documented: Zinc Alloy (Mazak), Steel, Aluminum, and brass. Mazak is, by far, the most common, followed by blued steel. A small number of aluminum mouthpieces are known, along with a single brass mouthpiece example (discussed below). Scabbard makers included:

Sheffield Steel Products of Sheffield, Yorkshire. Sheffield Steel Products produced approximately 670,000 Mk. 1 scabbards. Vanden Plas (Eng) 1923 Ltd. of Kingsbury Rd., London produced approximately 950,000 Mk. 1 scabbards.

| Early blued steel mouthpiece marked: "No. 4 Mk. I"

The following maker marks are pictured at left: N64 = Sheffield Steel Products S.S.P. = Sheffield Steel Products S.286 = Vanden Plas (Eng) 1923 Ltd.

|

||||||

| Unusual Mk. I Scabbard Variants | Brass Mouthpiece:

This scabbard is pictured on page 133 of Graham Priest’s book, Spirit of the Pike - British Socket Bayonets of the 20th Century. According to the author, the example in my collection is still the only brass-throated scabbard reported. Speculation is that it may be a prototype from a design proposal that was not adopted. |

n/a | 8.25 | 210 | n/a | None. | |||

|

Integral Leather Belt Frog:

The scabbard is a Mk. I with the broad-lipped steel mouthpiece. The leather belt frog is of unknown origin. It carries the scabbard with the frog stud inwards, where belt frogs almost universally carry scabbards frog stud outwards. The leather is quite thin, suggesting that this might have been done for civilian (e.g., police) use, rather than military use. The frog measures 4.875 in. (125 mm.) long by 1.75 in. (45 mm.) wide at the extremes. |

n/a | 8.25 | 210 | n/a | None. | |||

|

Mk. II | This uncommon scabbard has parallel sides and is made of very lightweight steel tubing.

According to Skennerton, 25,000 experimental Mk II scabbards were manufactured by the Franco-British Electrical Company, Tempel Park, Hurley. However, these scabbards are encountered far too frequently for only 25,000 to have been made. The number actually produced is believed to be 250,000. | n/a | 8.25 | 210 | n/a | Scabbard (Throat): broad arrow proofmark

Scabbard (Bottom): "S191" S191 was Franco-British Electrical's dispersal code. |

||

|

Mk. III | Plastic Mk. III (substitute) scabbard with parallel sides and oval frog stud. According to Skennerton, these scabbards were most likely made in North America, either the USA or Canada. | n/a | 8.25 | 210 | n/a | None. | ||

|

M5 | The U.S. M5 scabbard was made by Beckwith Manufacturing Co. of Dover, New Hampshire. Popularly known as the "Victory Plastics" scabbard, it was unique in design compared to all other No. 4 bayonet scabbards in having an integral web belt frog. These were supplied to the British under the Lend-Lease Act. | n/a | 12.75 | 324 | n/a | "VP" on reverse. | ||

|

No. 4 Securing Tab | Officially adopted in July 1940 as the: Tab, Securing, Bayonet No. 4 Mk. I. The securing tab retained the No. 4 Mk. I scabbard in web belt frogs made for use with the Pattern 1907 bayonet.

The tab measures 4.75 in. (120 mm.) long by 0.8125 in. (21 mm.) wide. Although troops often resorted to more expedient means of modifying frogs to retain No. 4 scabbards, the Securing Tab remained in British Army stores until the mid-1970s. |

None. | ||||||

|

Mine-Probing Equipment for No. 4 Bayonet | Entrenching tool with helve (handle) that accepts the No. 4 spike bayonet. With the bayonet fixed, the helve was used to probe for land mines.

The entrenching tool was made by William Hunt & Sons, The Brades Ltd., Brades Steel Works, Oldbury, near Birmingham. In correspondence, Anthony Carter indicated that Brades was the maker of many of the entrenching tools. He also indicated that P.S.S. was a firm called Princess Silk Shades, who made webbing during the War. AA5081 is the stores catalogue number. AA was webbing. | Tool: "BRADES" over "1944" over broad arrow proofmark

Helve: "M.H.B." "1951" and broad arrow proofmark Cover (Inside): "P.S.S. broad arrow proofmark 1943" over "CAT. No. AA5081" |

||||||

| Top | |||||||||

| © Ralph E. Cobb 2009 All Rights Reserved | |||||||||